The engine on your walk-behind mower is becoming too hot (Troubleshoot 7 Causes)

It smells like there’s been a lot of heat in there, and it could possibly start smoking. If you keep using your mower even after discovering an issue with it and attempting to remedy it, you may do irreparable harm to the engine.

It is possible for the engine of a push mower to overheat if the engine oil level is too low, if the incorrect kind of engine oil is used, if the air filter is clogged, or if the cooling fins are blocked.

If you run the push mower with a plugged mower deck, dull mower blades, or at a ground speed that is too fast for long, thick, or wet grass, you may overwork the engine, which can cause it to overheat. Another cause of engine overheating is running the push mower at a ground speed that is too fast for long, thick, or wet grass.

While using your push mower, it is imperative that you comply with all of the safety rules that are described in the operator’s manual. After putting the lawnmower in park, removing the key from the ignition, waiting for the engine to reach operating temperature, and then removing the spark plug boots, you are ready to begin any necessary repairs.

Table of Contents

This Is the Reason Why Your Push Mower Gets Too Hot

1. Using a gas-powered push mower with the incorrect kind of engine oil

The engine oil not only serves to keep the moving parts of the engine lubricated, but it also contributes to the engine’s ability to stay at a steady temperature. While working on a smaller engine, it is very necessary to choose the suitable oil due to the fact that there are distinctions between the various types of engine oils.

It is important to note that the kind of oil that must be used in the engine of a lawn mower that is air-cooled is distinct from the type of oil that must be used in the engine of a lawn mower that is liquid-cooled.

A high quantity of zinc is often found in the air-cooled engine oil used by gas-powered, tiny engines like those used on push mowers. Zinc is an ingredient that is added to products to act as a chilling agent.

Since it employs water in a liquid to cool the engine, regular motor oil, such as that which is used in a vehicle, does not include a significant amount of zinc.

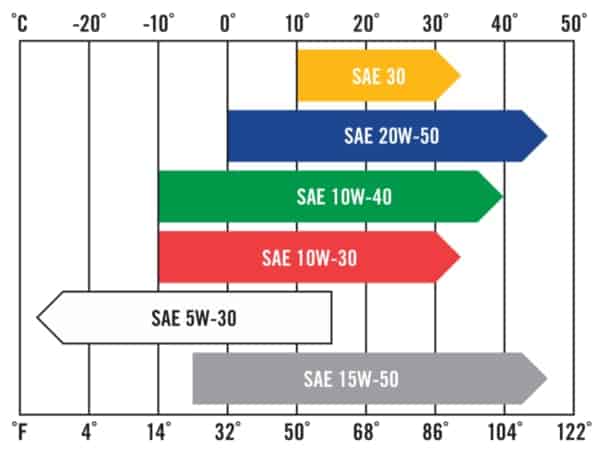

The following chart provides an overview of the various types of oils and the temperatures at which they perform optimally.

Utilize this chart, and reference your operator’s handbook for the manufacturer’s suggestion for oil. Keep in mind that the manufacturer’s advice will differ from this chart’s recommendations.

The majority of manufacturers of small engines that are used on push mowers will suggest using engine oil with a viscosity of either SAE30 or 10W-30 in the engine of your lawn mower. But, if you are going to be working at higher ambient temperatures, you should probably modify the viscosity of your oil to 20W-50.

SOLUTION: Remove the incorrect oil from the engine, then replace it with the appropriate air-cooled engine oil.

Kawasaki Engine Oil Viscosity & Temperature Chart

Kawasaki Engine Oil Viscosity & Temperature Chart2. An Insufficient Amount of Engine Oil in a Push Mower

For the engine’s internal components to be able to move without restriction, the engine has to be properly lubricated. When there is not enough oil in the engine, friction increases, which in turn causes the engine to get hotter.

If you continue to run an engine with a low oil level, the oil will continue to burn more slowly and get thicker. This may cause substantial engine damage.

Before utilizing the lawnmower, it is essential to do an oil check on the engine. If you feel that there is not enough oil, add some more.

If the oil level in the push mower is frequently low, check for the following issues:

- Leak of Oil – Inspect the area around the engine for any indications of a possible oil leak. As soon as you determine what caused the leak in the first place, replace the gaskets that the oil is entering through.

In the event that your mower has a filter, this is another component that needs your attention. Check that the oil filter is correctly sealed before using it. - Burning Oil – check to see whether the air filter is clogged. If the air filter is clogged, oil will burn off from the engine, which will make the engine function more difficultly. It is possible to clean the air filter, but if it is really unclean and cannot be cleaned, you will need to replace it.

- The consumption of oil– is a symptom of overheating, which may occur when an engine is in operation and cause the engine to consume oil. It is also possible that this is an indicator of a problem with the valves or the rings. You should bring your lawn mower to a service shop so that the engine may be inspected.

SOLUTION: Be sure to check the level of the engine oil, and top it up if it’s below the recommended amount. If this is the case, a thorough oil change should be performed to confirm that you are operating with excellent, clean oil and that the problem has been resolved. It’s possible that a heated oil become more viscous.

If, after changing the oil, you are still having issues, it is possible that you did substantial damage to your push mower by using it while the engine oil level was too low and continuing to use it.

If your lawn mower has to be repaired, take it to a small engine dealer or a technician. In order to assess the full scope of the problem, the technician will need to do some further tests.

3. The engine cooling fins on a push mower have been damaged or clogged with debris.

The cylinder head and the engine block are kept at a comfortable temperature thanks to the cooling fins, which are responsible for forcing air to the outside of the engine.

- There is a fan mounted on the top of the engine. It draws in new air that is cooler than the surrounding air and then blasts it down toward the base of the engine.

- The hot air is expelled from the bottom of the engine after the air has been routed through all of the heated components of the engine.

It is possible for the cooling fins to become broken or clogged with dirt, either of which would result in an inability to circulate enough air around the engine. Because of this, the engine may get overheated.

SOLUTION: Remove the cover from the engine, and clean the air intake and exhaust vents on the interior. In the event that you find any damaged fins, you are obligated to replace them with brand new ones. Remove any dirt that may have collected on the engine cover and in the areas around it, and then clean the rest of the region.

From now on, be sure to include this in the usual maintenance you do once a year.

If you wash the engine on your push mower, dirt and water will be forced into the area where the engine is situated, which will make the condition much worse than it already is. You should avoid shooting water into the engine of your lawn mower when you are cleaning it since doing so will just make the problem much more severe.

4. An Air Filter that Is Blocked on a Push Mower

It is the job of the air filter to ensure that the engine is supplied with clean air so that dirt does not cause wear on the engine.

If the filter is not regularly cleaned and maintained in excellent condition, it is possible for it to get so clogged with dirt and debris that it prevents air from reaching the engine.

Because of this, the engine of the push mower has to work harder to breathe, which may cause it to get heated and even overheat.

SOLUTION: Take off the air filter so you may examine its current state.

The air filter should be cleaned and replaced on a regular basis. To maintain the air filter in excellent condition throughout the mowing season, it should be cleaned many times during the season and replaced once a year.

If you use your push mower in dusty circumstances or if you use the mower more often than the typical homeowner, you may find that you need to repair or clean it more frequently.

To clean the paper air filter on a push mower:

- Take out the air filter and place it somewhere safe.

- Remove any traces of dirt that may still be present in the housing. Take extra precautions to ensure that no dirt gets into the air intake.

- Strike the filter you’re using against a hard surface. The goal here is to loosen and dislodge as much dirt from the filter as possible so that it may be removed.

- Make sure that you can still see light shining through the paper element of the air filter by holding it up to a light source and checking it. You should feel free to reuse your air filter as long as it is in good condition and you are able to do so. If you are unable to do so, it is time to purchase a replacement.

- Replace the air filter and ensure that the housing cover for the air filter is securely fastened.

- If your air filter additionally makes use of a foam pre-filter, you should clean the filter using a gentle detergent and some water. After washing, let the item dry in the open air. On the pre-filter, OIL SHOULD NOT BE APPLIED AT ANY TIME.

To clean the foam air filter on a push mower:

- Take out the air filter and place it somewhere safe.

- Remove any traces of dirt that may still be present in the housing. Take extra precautions to ensure that no dirt gets into the air intake.

- To remove any dirt that may have accumulated on the filter, wash it with a gentle detergent and water.

- Rinse until every trace of the soap is gone. Squeeze any excess water from the filter, then spread it out to dry on a flat surface.

- When the filter has been cleaned and allowed to dry, you may lubricate it with engine oil or filter oil. Put just enough water on it so that it is gently saturated with oil, but not so much that it is dripping with oil. Apply some pressure to the filter in order to remove any surplus oil.

- It is necessary to get a new foam filter if the existing one is severely soiled, has black stains, or rips in it.

- Replace the air filter in its housing.

Avoid being miserly and work on extending the life of the air filter as much as you can. I am highly careful of my finances and make sure to invest money on necessary upkeep things.

The amount of money that I spend on the air filter is a lot less than the amount of money that I would have to spend on an engine repair or replacement if debris got into the engine cavity.

5. The Deck of the Push Mower Is Completely Clogged With Debris

The deck of your mower has to be scraped clean on a regular basis so that any accumulation of grass clippings, dirt, and other debris may be removed.

Because of this accumulation, there is less space beneath the deck that can be utilized to generate air circulation, which is necessary for a beautiful cut. Also, because of this, the engine has to work harder in order to spin the blade while it is moving through the debris.

SOLUTION: Use a deck scraper to remove debris from the deck of the mower. It is also possible to use a putty knife or a wire brush.

Check the condition of the mower deck often to ensure that it remains clear of debris.

While there are treatments available to protect the bottom of the mower deck and assist prevent accumulation, these products are not widely available. But, these products are not miracles, and you will still find that you have some accumulation after using them.

You should try to avoid cutting damp grass and run your mower at full power in order to decrease the amount of clumping and accumulation that occurs beneath the deck.

6. Blades that are not Sharp on a Push Mower

A blocked mower deck will become an even bigger issue if you have dull mower blades.

Not only will the engine have to work harder to turn the blades through the material that is beneath the deck, but the engine may also overheat as a result of the strain caused by trying to move dull blades through the debris, which places a load on the engine.

SOLUTION: Regular maintenance and sharpening of the mower blades is required. Sharpening the blades of lawn mowers should be done about every 25 hours or twice per season for the typical homeowner.

7. Exerting too much strain on the engine of the push mower

It is in your best interest to do an analysis of the circumstances under which you mow in order to figure out how to get the greatest performance out of your mower.

While mowing a lawn with long, thick, or damp grass, the engine may be placed under additional strain. It is possible that this may cause it to overheat.

SOLUTION: You will need to run the mower at a slower ground speed while cutting through long grass, thick grass, or damp grass. If you want to get a beautiful cut while also reducing the strain on the engine, follow these tips:

- You should avoid mowing grass that is moist.

- Long grass should be trimmed twice or even three times. As part of this operation, the mower deck height will be adjusted to its most elevated position. Perform the first cut. After that, bring the deck level down a little and proceed with the second cut.

- Mow the lawn at a high engine speed with the throttle all the way forward.

- When mowing long grass, thick grass, or damp grass, reduce the speed at which you move the mower.

Are You Still Experiencing Issues with Your Push Mower?

It is quite possible that owners of push mowers will experience a lot of the same troubles throughout the length of the lifespan of their machines. Even if you splurge on a top-of-the-line mower and spend all of your money on it, it is almost inevitable that it will give you trouble at some point during its lifespan.

I have produced the following guide for your use in the hopes that it will be of use to you in discovering the reasons behind these difficulties as well as the answers to them: Problems that often arise with push mowers and the solutions to those problems