Craftsman LT2000 Drive Belt Diagram & Explanation That You Need!

There cannot be enough emphasis done on the fact that drive belts are for sure, one of the leading parts that your riding mower must own. And trouble in this part, or having less understanding of it, may bring difficulty with usage, maintenance, and more.

We are covering the Craftsman LT2000 drive belt diagram today. But along with more relevant information to it, so that you have a comprehensive idea on the whole matter by the end!

Make Sure to Stick till The End!

Table of Contents

The Craftsman LT2000 Drive Belt Diagram, Parts Explanation, Mechanism & Frequently Asked Question

Let’s sort all the topics one by one, starting from the demonstration of the drive belt.

Here’s the much-awaited Craftsman LT2000 mower drive belt diagram.

Here’s more in-depth about the parts that we have numbered in the Craftsman LT2000 drive belt diagram given above.

Left Hand Double Pulley

Because of the part, there’s less effort necessary for moving loads. And it happens due to double pulling helping in increasing the overall mechanical advantage of a system.

In a compound pulley mechanism, there’s more than just one pulley. And adding these helps in dividing the overall load. Eventually, this makes the load easy to move.

Right Hand Double Pulley

Similar purpose to the left-hand double pulley. It’s just located on the right side, and its overall function refers to the same purpose. So, we are not going in-depth on this.

Center Pulley

This is the craftsman LT2000 drive belt pulley located in the center. To hold a rope wire rope or belt there can be a grooved wheel. This sheave or pulley wheel can be incorporated into a pulley.

There should be an axle or bearing located on the pulleys inside the frame that allows the sheave to spin. The part stays on the very center of the Craftsman LT2000 deck.

Deck Idler Pulley

Then there’s the deck idler pulley. The main job is to make sure there’s enough tension and guide for the drive belt of the engine.

The belts need to wrap around several components of the engine. And these are the alternator, water pump, power steering pump, and so on.

Self-Tapping Screw Assembly

There are certain types of fasteners that can laterally drill on their own while being screwed to materials that can be metal, plastic, or wood.

And these are called self-tapping screws. For precise fit thread making, both self-tapping screws and screwdrivers are used typically

Deck Belt

There should be a deck belt that is basically a compulsory element of the riding lawnmower. As it needs to make the connection between the crack shaft as well as the blades of the lawnmower. And eventually, that helps in turning the part.

You must always consider changing the deck belt if ever notice any cracks being formed on the rubber. Replacing a broken deck belt is also necessary to ensure interruption-free mowing.

A Deeper Look at The Working Mechanism

The most prominent job of a drive belt is ensuring there’s power transferred to all the parts of the mower. There’s radial torque with the engine shaft of the mower and the drive belt needs to transfer this torque towards the transmission’s input shaft.

And then the torque will allow the mower to function. So that the whole performance can smoothly continue. There’s also a link to moving the mower forward as well as letting the blade spin.

But How Can Drive Belt Transfer Power?

This is a common confusion that a few can have. And not understanding how the drive belt has the ability to move torque from engine to transmission will keep things incomplete.

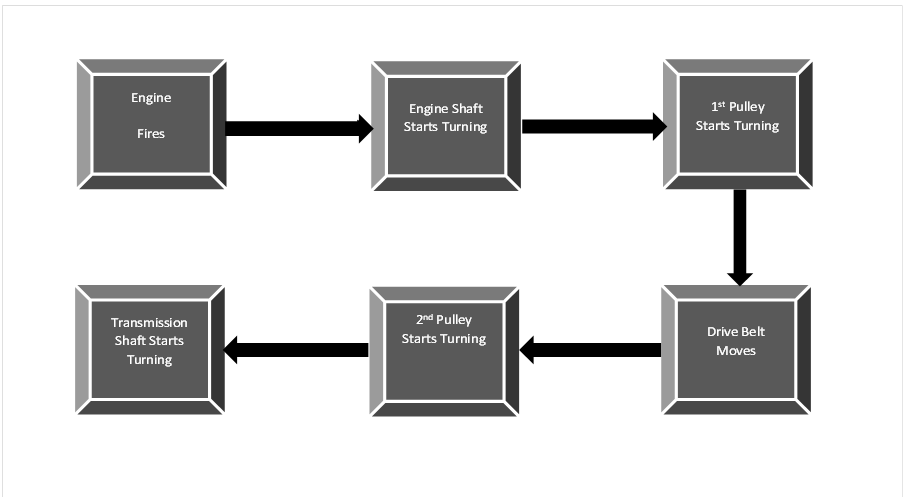

The answer is in the way the drive belt runs on the mower. There should be pulleys’ attachments with the input shaft as well as the engine shaft. As soon as the engine is fired up, it will turn the engine shaft. Later the input shaft of transmission also turns.

Read Also: Kohler Starter Solenoid Wiring Diagram & More!

The drive belt can move due to the first pulley. And then with the help of a moving drive belt, the 2nd pulley gets to move as well. The 2nd pulley stays connected to the transmission’s input shaft. So, when the pulley moves, it leads the transmission shaft to move as well.

And hence, the whole movement pattern becomes complete like that.

Here’s a demonstration of what happens

After the transmission shaft received the power, it transfers some to the mower’s drive wheel. And that makes the whole mower move basically. So that’s basically how the drive belt helps in allowing your mower to go back and forth.

A Helpful Tutorial You May Need!

Frequently Asked Question (FAQs)

What is the craftsman LT2000 drive belt size?

It’s 1/2 x 95.5 inches. For proper craftsman LT2000 drive belt installation, having the right size is crucial.

How long is the drive belt on a Craftsman Riding Mower?

Most of the craftsman mowers will have two drive belts, one is primary while the other is secondary. And these can range in length between 42 to 50 inches on average. This strictly depends on the model one is referring to.

Can you adjust the drive belt on a Craftsman lawn mower?

If you are talking about blade drive belts that come on the craftsman lawn mowers, then there’s no need for adjustments. The manufacturer instead recommends going for a replacement whenever there’s something wrong with the belt.

Why does my drive belt keep coming off my riding mower?

There can be many reasons for such happening. However, in common scenes, it’s due to the bearings of pulley or spindle housings, belt keepers, brackets, or a part associated with being worn out. There can also be debris that is not allowing proper tension to the deck belt. Hence the trouble.

How long should a mower drive belt last?

Well, it really depends on how much usage you get from it. But in the typical scene, the drive belt should last you 3 to 4 years.

Wrapping Up

And we provided you the craftsman LT2000 drive belt diagram with parts explained, the whole mechanism demonstrated as well as answers to your most asked queries.

We hope it was comprehensive enough for you to get the information you’re looking for. If not, then maybe consult an expert directly, and let them solve the specific type of issue you are facing.

Maybe things are more complicated than it seems. And you should not delay in getting help to having the mower back on track working as it should

See You Again in Another P