11 Reasons Why Your Push Mower Isn’t Working When It’s Hot: FIX IT!

Your lawnmower suddenly stops working after you’ve been using it for a while. I’ll go over a few potential culprits so you can give your mower another go at starting up.

Some of the most common causes of a push mower shutting down when hot are a clogged air filter, an incorrect oil level, a dirty carburetor, faulty fuel cap, old fuel, a faulty spark plug, a faulty ignition coil, obstructed cooling vents, and a clogged mower deck.

Be sure to stick to the guidelines for preventing accidents that are included in your manual. The engine must be allowed to cool and all moving parts must be still before proceeding. To begin fixing the spark plug, you must first remove the wire from the plug.

Before diagnosing, repairing, or using your equipment, be sure to read and follow all safety instructions in the owner’s manual. If you don’t feel confident in your ability to safely make the necessary repairs, it’s best to call in a pro.

Table of Contents

Why Does a Push Mower Quit When It Gets Hot?

The Push Mower Dies Due to a Clogged Air Filter.

The filter must be checked. Without routine maintenance, it can become so clogged with dirt and debris that the mower will stop working. The lack of air is starving the engine of the fuel it needs to function.

As a piece of preventative maintenance, replacing the air filter is essential for keeping dirt and debris out of the engine. It’s important to maintain a tidy environment.

It can cause the push mower to overheat, which can cause it to stop running and may even damage the engine.

A new air filter should be installed at the beginning of each mowing season. It needs to be cleaned and checked on several times a year.

When using a push mower in extremely dusty environments, you should expect to clean and substitute it more commonly.

The filter on a push mower is easy to check and clean. Taking the time to test the air filter can prevent much bigger issues down the road.

SOLUTION: Take out the filter and clean it separately from the housing. Try not to smudge the air filter.

Use a dry, clean cloth to remove any residual dirt from the housing. To clean the filter on a push mower, do as follows:

To clean the air filter on a paper lawn mower, you should:

- A paper filter element can be cleaned by tapping it against a hard surface to dislodge dust and debris. Get out as much grime as you can. Do not clean the filter with compressed air as this will cause permanent damage.

- You can test your filter by holding it up to a light and seeing if any light gets through the paper.

- If the filter paper has become transparent, it can be reused. When the air filter is so dirty that light cannot pass through it, when it becomes wet, or when it is otherwise damaged, it should be replaced.

- Return the housing cover to the air filter after installing the filter.

To maintain a foam air filter for a lawn mower, you should:

- NOTE: Learn how to use a primary foam filter by following these steps. Foam pre-filters can be used in addition to the primary filter, but NOT with these.

- It’s important to inspect the condition of the foam air filter. If it becomes dry, brittle, torn, or has brown spots, throw it away and get a new one.

- You can wash your filter with some mild soap and water if it’s in good shape. Clean the filter of any oil and dirt.

- The filter needs to be rinsed until all traces of soap are gone and the water runs clear.

- Arrange flat and let dry in the air. If you want it to dry more quickly, put it in direct sunlight.

- Coat your filter with filter oil. The filter should be squeezed to remove any excess oil. You shouldn’t have oil dripping from the filter. (A foam pre-filter should never be oiled.)

- Put the filter back in the filter housing and replace the cover.

A Push Mower Stops Working Due to Old Fuel

In many cases, the fuel in a push mower has simply gone bad after prolonged use. That’s because varnish and sticky deposits left behind by old fuel can lead to equipment breakdown and fuel restrictions if they’re not removed.

If the engine is deprived of enough fuel, it will sputter and eventually stop working. Never use old gasoline or gasoline with a high ethanol content in a push mower.

Gasoline with less than 10% ethanol concentration is recommended for use in push mowers. Although fuel with no ethanol is preferable, gas with more than 10% ethanol should never be used.

Find out what kind of engine you have so you can figure out how much gas you’ll need.

- Straight gas is required for 4-cycle push mower engines.

- Gasoline and 2-cycle engine oil are required for 2-cycle engines in push mowers.

FIX: With a siphon pump, empty the fuel tank into a safe container. If the fuel line can be disconnected from the carburetor, the fuel can be drained into a catchbasin.

Clean the fuel system, lower moisture content, and stabilize the fuel with the help of a substitute fuel like Sea Foam Motor Treatment, which can be added to a fuel can along with fresh fuel. For this reason, I always put Sea Foam in my gas tank.

A clogged carburetor causes a push mower to fail

Carburetor controls how much fuel is introduced to the cylinder for combustion with air. Old fuel’s varnish can harden and clog pipes, rendering internal components useless.

By doing this, you’ll cut off the fuel supply to the mower’s motor, effectively killing it.

To make sure a dirty or faulty carburetor is actually the cause of your car’s running issues, there are a few tests you can run before taking it apart. As a first step, check the fuel supply to the carburetor.

As a second step, take out the air filter and spray some carburetor cleaner into the air intake. Kick off the mower. If it starts up but dies after a short while, you need to clean the carburetor.

SOLUTION: Cleaning your carburetor isn’t too difficult if you have a basic understanding of mechanics and don’t mind dealing with a lot of tiny pieces. To clean the carburetor on your lawn mower, just use these steps.

If you don’t feel like dealing with the carburetor yourself, you can always take it to a lawn mower repair shop.

Misusing a Push Mower with the Wrong Type of Engine Oil

Air-cooled engine oil with a high concentration of zinc is ideal for your push mower. As a refrigerant, Zinc is put to good use.

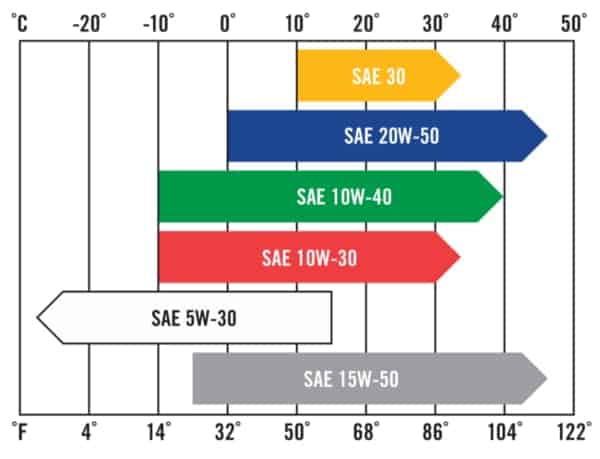

Unlike automobiles, the cooling process is different. The engines of automobiles are cooled by liquid, while those of smaller engines are cooled by air. There is a consensus among manufacturers of small engine lawn mowers that SAE30 or 10W-30 engine oil is the way to go.

While this is generally the best option, it may be necessary to switch to a different viscosity, such as 20W-50, when working in hotter environments.

Kawasaki Motors has provided a chart to help you choose the right oil for your lawnmower’s engine.

An overheated engine is the result of using the wrong type of engine oil.

SOLUTION: If you discover the oil is incorrect, you should change it out and replace it with new, air-cooled oil.

A Push Mower’s Engine Dies From Lack of Oil.

Before starting your mower’s engine, make sure the oil level is at the proper level. Low oil levels in the engine can cause the push mower to shut down.

The engine’s moving parts need oil to stay lubricated. It’s important to keep enough oil in the crankcase to prevent excessive heat and friction from being produced by the engine’s moving parts.

Extreme temperatures can cause oil to thicken and metal parts to melt. Damage to the engine can be catastrophic if this happens. The push mower might need to be replaced.

SOLUTION: Attempt to adjust the engine oil level and start the mower to see if it starts up and operates normally. Having your mower shut down because of low oil means you’ve probably already done significant damage to the engine.

In order to ascertain how much damage has been done to your engine, you should have it checked out by a professional small engine mechanic. If you keep on using your lawn mower with the oil level too low, you’ll eventually have to replace the engine.

Rather than repairing an existing push mower, replacing the engine is usually the most economical option.

A push lawnmower’s engine will die if you put too much oil in it

Keeping an engine’s oil level at least halfway full is common knowledge. On the other hand, they don’t always realize that having too much oil in the crankcase can also damage the engine.

When engine oil is overfilled into the crankcase, the crankcase pressure rises.

Crankshaft and rod are impeded in their motion because too much oil is in the way. When this happens, the engine’s internal components may overheat and eventually fail.

In addition, when the mower is overworked, oil is forced into the cylinder via the valve train, producing a dense plume of smoke as the oil is burned off.

There’s a risk that breathing this smoke will cause your car to die.

SOLUTION: Drain the oil until it reaches the level indicated by the oil dipstick. To avoid accidentally starting the engine, remove the wire from the spark plug before you begin.

There should be a drain plug or oil fill port for removing excess oil. A turkey baster is a handy tool for draining off excess oil with minimal mess.

After draining some oil, use the dipstick to make sure there is still enough oil in the engine. To adjust the engine oil level, drain and/or add oil as necessary.

If your mower was smoking before it stopped working, you should check to see if the air filter got clogged. It’s time to reconnect the wire to the spark plug (s).

After checking and adjusting the oil level, if you are still having issues, you should take your vehicle to a mechanic who specializes in fixing motor vehicles.

A damaged or clogged engine cooling fin causes a push mower to stop working.

The engine block and cylinders benefit from the cooling fins’ ability to force air over them. Maintaining the cooling fins clean and free of debris is essential for proper air circulation around the engine.

The engine can overheat and die if it is not properly cooled.

SOLUTION: Clean up the area around your cooling fins and fix any that are broken. You should clean up the grime that has accumulated on the engine shroud.

The Push Mower Dies Due to a Faulty Spark Plug

Lack of spark can be caused by a dirty spark plug with carbon buildup, broken porcelain, or a burnt electrode. A manual lawn mower will stop working if you do this. To get your mower going, it may have supplied enough of a spark, but it won’t do much after that.

To solve this problem, first make sure the plug hasn’t accumulated any grime on its tip, and then clean it if necessary. In the event that you notice the tip is extremely dark or if it is damaged, you should replace the spark plug.

It’s also possible that the spark plug wires aren’t properly connected, in which case you’ll need to check those.

A faulty ignition coil causes a push mower to break down

A coil’s windings can become unwound and cause a short when the coil is heated. As the spark plug requires voltage, this is where the coil comes in. The engine on the manual lawnmower will break.

SOLUTION: Check the continuity of your ignition coil with an ohmmeter to make sure it is working properly. When the coil fails, it must be replaced.

Failure of a Push Lawnmower Due to a Clogged Fuel Cap

The fuel cap on a push mower is perforated so that air can flow freely through it. The fuel tank’s internal air pressure will remain stable at this setting.

Carburetor not getting gas due to vacuum in tank caused by missing vent cap. The push mower may suddenly stop working after prolonged use.

SOLUTION: Run your mower with both the gas cap clamped and loosened to let air into the tank to see how well it seals.

Assuming the push mower runs fine when the cap is loosened but eventually shuts off when tightened, the fuel cap is likely the culprit.

Get a new fuel cap and install it.

A clogged mower deck and dull blades cause a push mower to fail.

Grass and dirt that collect on a mower’s deck can cause the engine to overheat and die.

To turn the mower blade(s) through the blocked deck, the engine must work harder. It’s already a big deal when you run a push mower with worn-out blades.

SOLUTION: Sharpen your mower blades and scrape your deck on a regular basis. It prevents your engine from overheating while also giving you a cleaner shave.

Don’t mow when it’s wet out to avoid a buildup of grass.