Looking For Briggs and Stratton Governor Linkage Diagrams?

The popularity of their air-cooled petrol engines has made Briggs & Stratton the world’s hugest producer in the industry indeed. And for outdoor equipment, they provide the best engines no doubt.

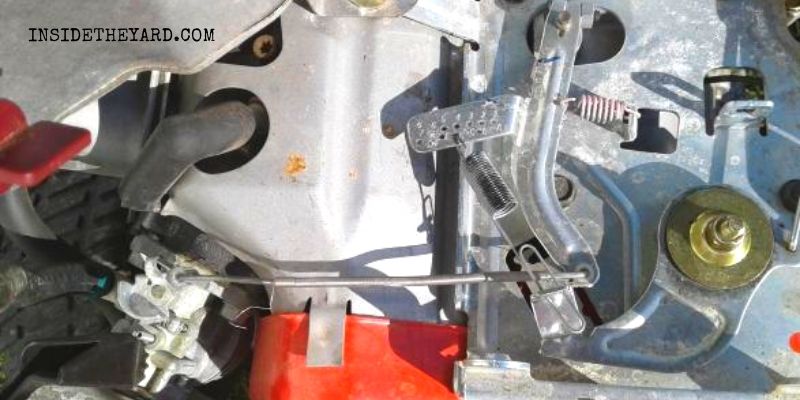

The engine however may face issues occasionally, just like any other engine that goes through constant use. And one very difficult to solve matter is locating the governor linkage area on the lawnmower engine.

To make the engine run at a consistent speed, you may want to do some throttle adjustment, which is the role of the governor linkage. So, it makes sense why anyone would need Briggs and Stratton governor linkage diagrams to locate the spot.

Table of Contents

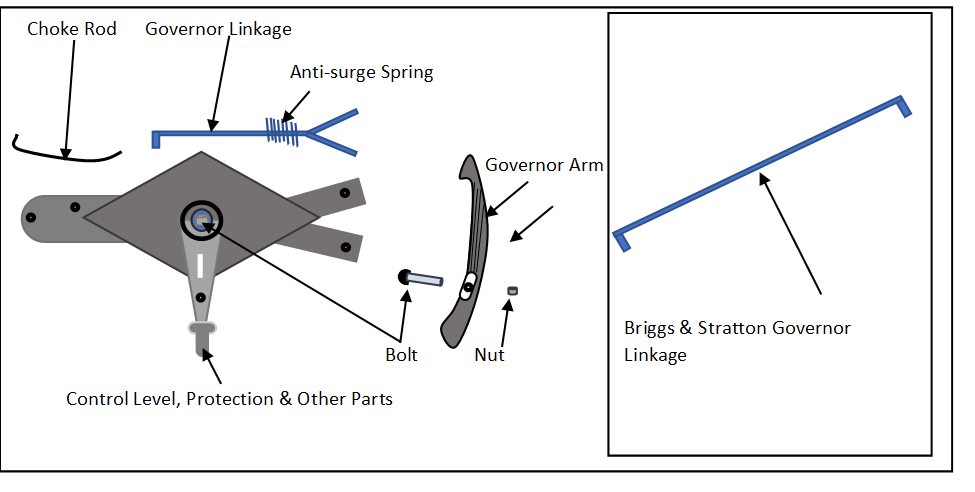

Here’s One of The Basic Briggs and Stratton Governor Linkage Diagrams to Locate

The Briggs & Stratton governor linkage is pretty straight in shape with slotted at 90-degree short ends.

Briggs and Stratton governor assembly includes kit idle speed adjustment, spring, screw, gasket, and so on.

If You are Dealing with a Backfiring Governor When Throttled

Often times this happens with Briggs and Stratton due to not having properly setup springs. To have a better idea of the springs, you can check the Briggs and Stratton governor spring diagram. And you may actually have to fabricate the governor linkage in that case for dealing with the random piling of parts.

The main principle to keep in mind here is the throttle’s open position. It should be in the open position, as you have the governor arm upwards, relaxed. Just have look at the throttle to verify exactly where it takes place.

Once you find out the location, you’re going to need a bike spoke for inserting the hook end at the end of the throttle. So that it can rest aside the governor. All the members should be already installed while you do so.

You also want to double-check that the throttle is open while the governor’s arm is also upward. Then with a 90-degree bend with the spoke, let it enter the arm.

Try pushing the governor arm downwards next. So that the throttle is all way close. And at the same time, the spring is now back to open.

Time for a final bend so that you can next move to the springs. One on the loop end or near and another part out the governor’s arm, there should be 2 springs. These should be going to the throttle control line connecting arm that moves.

Keep In Mind: The screws on the carb are highly sensitive. So be very cautious with adjustments.

This Video Will Help You Too!

Frequently Asked Questions (FAQs)

What is the purpose of a governor linkage on Briggs?

It is basically a part that is in charge of adjusting the mower throttle so that a consistent speed can be used for running the engine.

How to adjust the governor linkage on Briggs?

You have to locate the governor lever first and then check for the screw-on governor crank that holds the lever in place. Using a screwdriver loosen it to adjust the throttle plate linkage to a wide-open position next.

How to adjust the governor linkage on Briggs?

You also want to check the governor shaft’s movement. Then move the shaft or lever to the counterclockwise direction for having a vertical crankshaft or to a clockwise direction for a horizontal crankshaft.

This will bring the linkage to full throttle or high-speed position. You also want to adjust the screw with a torque wrench and ensure 35 to 45 in-lbs. torque. If the linkage is not binding or facing construction anymore, the adjustment worked. And you can start the engine to enjoy a consistent speed then.

How does Briggs and Stratton governor linkage work?

The speed-sensing device on a pneumatic governor is a movable air vane, made of metal or plastic. This small engine part registers the change in air pressure around the spinning flywheel. The pneumatic governor also relies on one or two springs to pull the throttle toward the open position.

Final Thoughts

Using the Briggs and Stratton governor linkage diagrams and following steps on solving whatever issue the governor is facing, does work for people who have a pretty solid idea of how these lawn mower parts work.

However, if it’s not something you are used to solving, contact a professional. Let them pay a visit and check what’s going on with your lawnmower. That way getting a solution would take less time and your equipment will be at less risk of facing further problems.