The RYOBI Generator Will Not Continue to Run (SOLVED)

During a building job, a power outage, or any other time when you need electricity but don’t have access to electric connections, your generator won’t continue to operate so that it can power the objects that you need the most.

When a RYOBI generator is overloaded, when it is short on engine oil, when it has a blocked spark arrestor, or when it isn’t receiving adequate air, fuel, and spark, it will not continue to operate.

This might be because the air filter is clogged, the fuel filter is blocked, the fuel line is clogged, the carburetor is filthy, the spark plug is dirty, the oil level is inadequate, or you are attempting to power more things than the load limit can handle.

Always ensure that you are taking all of the safety measures that are outlined in the RYOBI operator’s handbook. Taking this step involves removing the wire from the spark plug and waiting for the engine to cool down before attempting any repairs.

Table of Contents

1. The RYOBI Generator Cannot Handle the Amount of Load It Is Receiving

If you try to power more objects with the generator than it is able to manage, the generator may turn off or refuse to remain on. There is a range of load capacities available throughout RYOBI generators.

On the generator, there will be a notation indicating the load size. There will be a number that is provided for the beginning watts, as well as a number that is published for the running watts.

Starting watts refer to the additional watts that your generator is able to manage for a brief period of time while the item is being started (s). The running watts refer to the total number of watts that a generator is able to manage in order to keep an item operating (s)

If you try to power more things than the generator’s beginning or running load limit, it won’t continue to operate. This applies to both the starting load and the ongoing load.

SOLUTION: Check the load limit that is indicated on the generator to ensure that you do not plug in more goods than the generator can handle. The next step is to determine the total wattage needs of everything that you are trying to power at the same time.

Compute the total amount of watts required by all of the components that are active at the same time. The total amount of watts drawn from all of the components must be lower than the load limit of the generator.

To figure out the wattage capacity, consider the following advice:

- The wattage of the vast majority of electrical goods may be found on a tag that is connected to the item itself.

- When it comes to motors, there are those that need greater power in order to start anything. In this particular instance, the beginning wattage need to be used in the process of computing the starting wattage requirements.

- In order to obtain a total, you need to add up the wattage of everything that will be hooked into the generator at the same time.

- This total wattage must be lower than the maximum wattage that the generator is capable of producing.

2. The RYOBI Generator Does Not Have Enough Air

Verify that air can freely pass through the air intake and that it is not being constrained by a choke that is closed or an air filter that is clogged before you begin searching for an air restriction.

Plugged Air Filter

An air filter is used to safeguard an engine by preventing dirt from being drawn into the air intake. This is accomplished by filtering the air. Even a very little quantity of dirt may cause significant and long-lasting harm to an engine.

When the air filter is not cleaned on a regular basis and maintained in excellent condition, it runs the risk of being clogged with dirt. It’s possible that the engine won’t be able to pull in enough air to keep going.

SOLUTION: Take off the filter so that you can check the state of it. If the filter is broken or very unclean, you should get a new one and replace the old one. If it is in generally excellent shape but has a small bit of dirt on it, you should clean it.

Incorrect Adjustment of the Choke

When starting a cold engine, you are obliged to use the choke. When the engine reaches operating temperature, the choke lever needs to be moved from the on/closed position to the off/open position so that the carburetor throat may receive a greater quantity of air.

If the engine stops running shortly after it has been started, the problem may be caused by an improperly adjusted choke setting or by a choke that is jammed in the closed position. Check to see that the choke lever is set in the appropriate position.

If the choke lever is in the right position but you are still having problems with airflow, check the choke to see if it is stuck in the closed position and needs to be opened. To unclog a choke that is jammed so that it may be opened and closed, use carburetor cleanser.

3. The RYOBI Generator does not have enough Fuel

There are a few different reasons why a RYOBI generator could not provide the engine with enough fuel for combustion when it should.

Tank devoid of any fuel

You may have forgotten to check the gasoline tank of the generator, despite the fact that an empty fuel tank is the most apparent reason why the generator won’t keep running.

You might have a faulty fuel gauge or have developed a gasoline leak, both of which could have prevented you from recognizing that the tank was empty.

SOLUTION: Put some new gasoline in the tank. If one of these issues is discovered, you should fix any gasoline leaks and replace any fuel gauges that are malfunctioning.

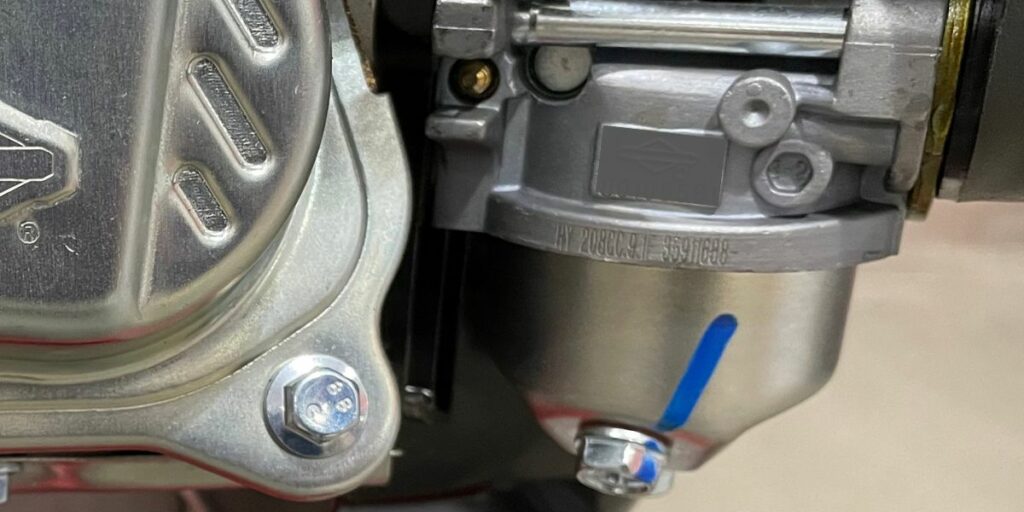

Carburetor Clogged With Gunk

The carburetor is responsible for controlling the quantity of fuel that is combined with the necessary amount of air during the combustion process. Old gas may, over time, leave a coating that prevents the carburetor from operating correctly, which in turn prevents the engine from receiving the gas it required to continue running.

SOLUTION: When this occurs, the RYOBI carburetor must be removed from the generator so that it may be cleaned using carburetor cleaning. This will remove the crusty buildup that is caused by residual old gasoline. When disassembling a carburetor, I think that taking pictures along the way helps ensure that it is put back together correctly.

Replace the carburetor with a new one if you don’t want to clean it yourself or if you can’t get the old one cleaned up and operating again, or take it to a company that specializes in repairing small engines to have the carburetor cleaned or replaced.

If you use fresh fuel in your RYOBI Generator and avoid having it linger for lengthy periods of time in your generator, you may help reduce the harmful impact that using old fuel can have on your machine.

Plugged Fuel Tank Vent

It is necessary for the gasoline tank to have a vent in order to let air to freely enter and exit the tank so that the air pressure may be maintained at a constant level. In the event that the fuel tank vent gets clogged, the fuel tank will develop a vacuum since the air won’t be able to enter the tank while the gasoline is being used up.

Because of the vacuum, gasoline won’t be able to reach the carburetor, which will cause the generator to operate inefficiently and eventually turn off.

On some RYOBI generators, the fuel tank vent is an integral part of the gas cap, whereas on others, it is a separate component that is mounted on top of the fuel tank. It is possible that there is an issue with the fuel tank vent if the generator turns off by itself and won’t turn back on unless the lid is loosened.

SOLUTION: Changing out the vent on the fuel tank.

4.RYOBI Generator Suffering from a Deficiency in Spark

Bad Spark Plug

A fouled spark plug may generate an inconsistent spark, which can lead to the engine running poorly or even stalling out completely. This issue may be brought on by a number of different things, including a faulty spark plug, loose spark plug wires, or an inappropriate electrode gap.

SOLUTION: Make use of a wire brush to clean a spark plug that is unclean. If, on the other hand, you discover that the spark plug is broken, worn, or an extremely dark color, you are required to replace it with a new spark plug.

A Problematic Ignition Coil

When the generator grows hot, the ignition coil has a greater risk of coming apart and creating a short. Since of this, the spark plug will not be able to produce a spark because it will not get the necessary voltage to do so.

To begin, check to see whether the spark plug is in satisfactory condition. After that, make sure everything is consistent.

SOLUTION: If you discover a gap in the continuity, you should replace it.

5. The RYOBI Generator has a Low Level of Engine Oil in It

The majority of RYOBI generators have a sensor that, in the event that the engine oil level drops too low, will trigger the engine to shut down. This is a safety device that guards the engine from the potentially disastrous repercussions of operating the vehicle when there is inadequate oil in the system.

If your generator turns off and the low oil indicator comes on, the first thing you should do is make sure the generator is sitting on a surface that is completely flat and level. The sensor may be triggered if the generator is placed on ground that is not level.

SOLUTION: Check the engine oil level using the dipstick that is connected to the oil cap after you have established that the generator is situated in the appropriate location.

Take off the top of the oil. Clean the dipstick by wiping it down with a fresh cloth. When you want to check the oil level on the dipstick, you have to remove the cap and the dipstick first. (Ensure that the cap is not reattached before obtaining the reading for the oil level.)

If the dipstick indicates that the amount of oil should be higher, then you should continue to add oil until it reaches the appropriate level.

If you check the engine oil level and discover that it is at the proper level, but the low oil sensor light continues to illuminate, you may have a malfunctioning sensor. Contact your local RYOBI generator dealer to assist.

6. A Spark Arrestor that Is Connected to a RYOBI Generator

On the muffler, there is a spark arrestor screen that serves the purpose of preventing hot exhaust material from being expelled from the exhaust system. It is necessary to have this screen in order to lessen the risk of burns and forestall fires.

When a spark arrestor screen becomes clogged with debris, it prevents the hot air from the engine from escaping, causing the engine to bog down and maybe turn off entirely.

SOLUTION: Take off the spark arrestor screen, and then clean it with any kind of liquid or a little metal brush. If you notice that it is damaged in any way, including having a hole in it, you will need to replace the screen with a new one.